Mould Making Process

Design & Engineering

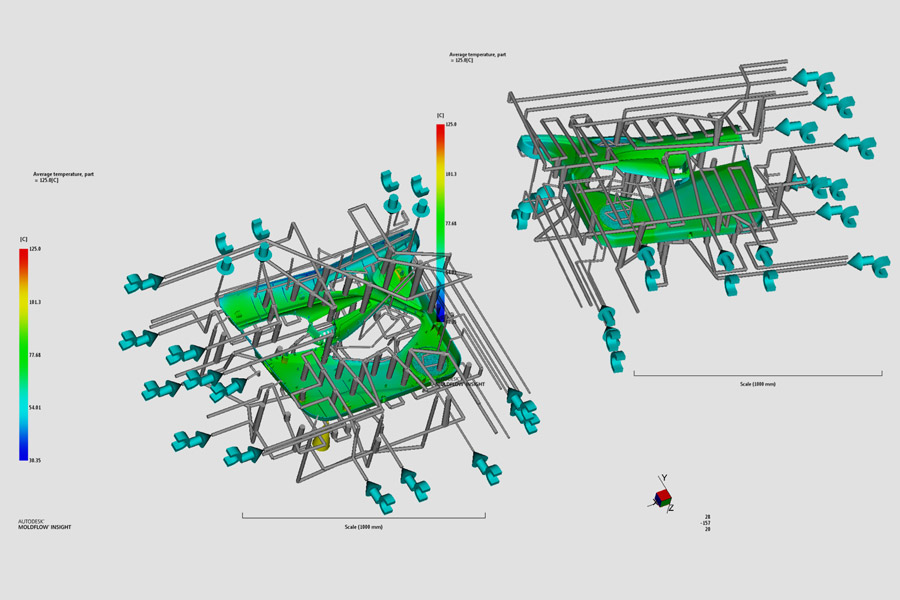

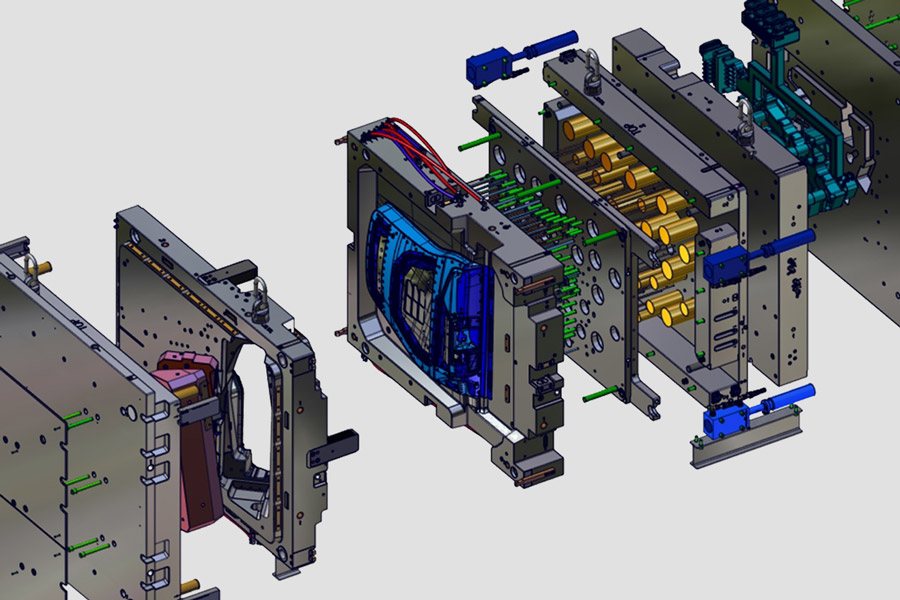

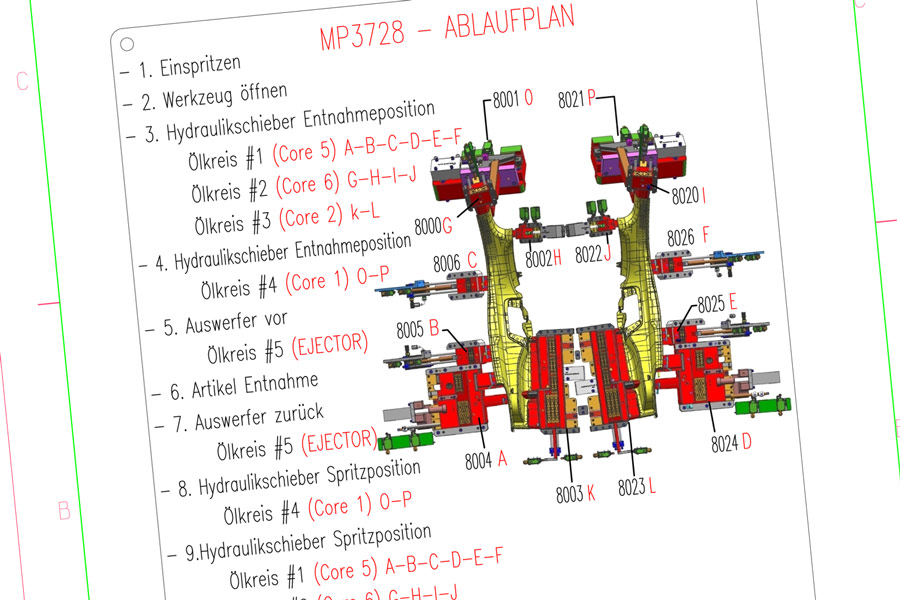

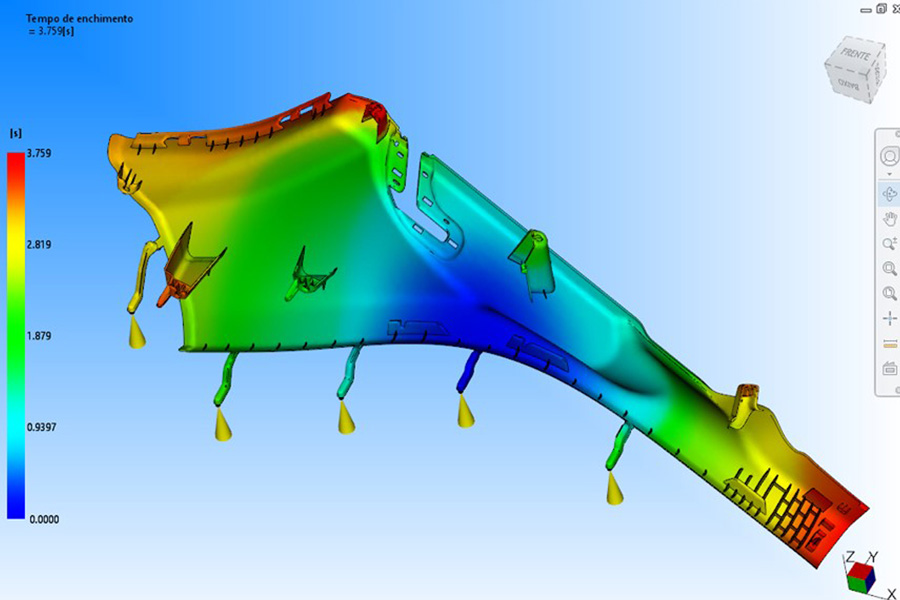

MOLIPOREX uses the most advanced technology (both software and hardware) for its mould engineering development. The continuous upgrading of hardware and the persistent search for knowledge allows MOLIPOREX to stand at the leading edge among its competitors.

Our team of passionate tool designers work on a range of solutions from PLM to rheological analysis, to CAD and 3D modelling.

2K/3K Injection | Over Moulding | In-Moulding Assembly | Gas Assisted Injection | Insert Moulding

Mould Making Process

Prototype Tooling

In today´s highly competitive market, OEMs are in constant evaluation and development of NEW ideas to stay apart in the eyes of their clients, and the differentiating element is that how fast they can bring an idea in to reality! MOLIPOREX offers wide range of rapid prototyping (at product design stage) and prototype tooling (at tool development stage) with extremely fast delivery times to support a very quick realization of development projects.

MOLIPOREX offers wide range of prototype tooling solutions from silicone tools to aluminium tools, complemented by full feasibility study for serial production tooling.

Mould Making Process

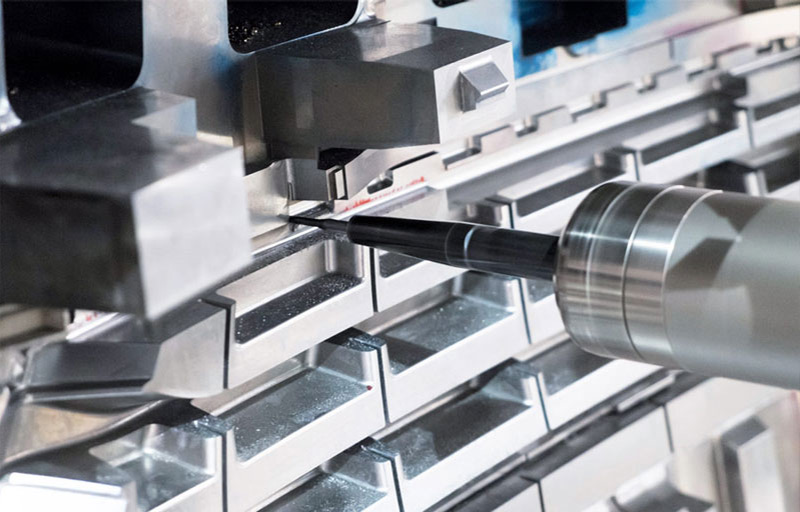

Serial Tool Production

With highly specialized 3 mould factories, MOLIPOREX stands among world´s BEST mould making companies. Each factory is specialized in different products categories following our fundamental principle of doing what we know the best. We deployed latest generation of high precision machining technologies from the best in class machineries, supported by our highly skilled design and production teams, enabling MOLIPOREX to offer state of the art solutions to our wide range of client base worldwide.

Mould Making Process

Try-Out Center

MOLIPOREX Try Out and Validation Center (MPCT) was installed to test a wide range of injection moulds and technologies. It has the best in class machineries and equipment in a friendly environment with its experienced engineers, who are among masters in process optimization. With well-studied investments at MPCT, MOLIPOREX is able to offer highly flexible process engineering solutions to its clients as a very important element in mould / product maturation process.

MOLIPOREX provides highly flexible solutions for almost all types of moulds and injection moulding technologies through our carefully selected injection machines ranging from 55T to 2300T. 2K and 3K injection, Gas assisted injection, and metal insert over moulding technologies are fully supported by the latest production equipment.

Mould Making Process

Quality & Inspection

We inbuild quality in the DNA of our moulds starting with a good design and precise engineering, and during various stages of mould development process implement precise inspection before moving to the next step. With the objective of “First time right” we go extra miles before the first try-out, to ensure the best results are delivered to our clients right at FOT stage.